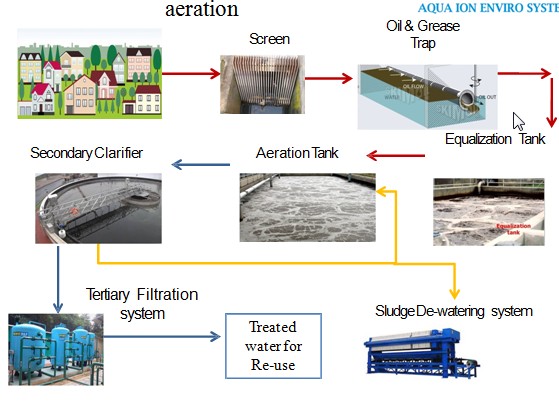

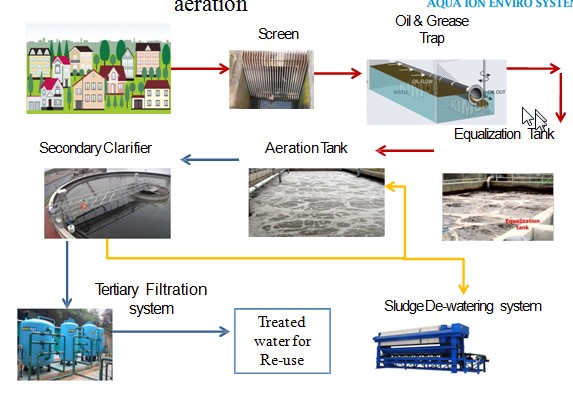

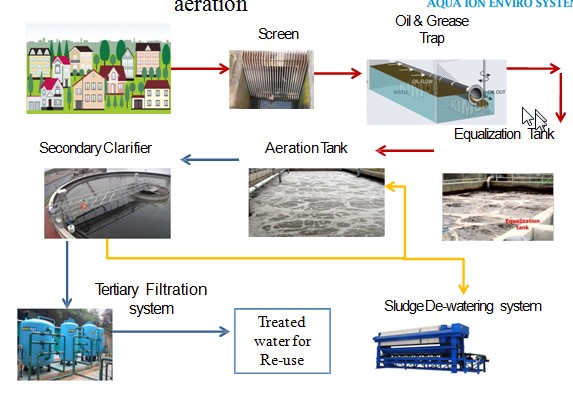

Treatment Process Technology

Activated Sludge Process – Extended aeration

- Widely accepted.

- Based on the concept of suspended growth.

- Aeration either by Surface Aerators or Diffused Aeration System.

- Requires sludge recycling and Sludge monitoring.

- Augmentations are possible with addition of media

SEQUENCING BATCH REACTOR – SBR

- Collection, Equalization, biological treatment, and secondary clarification can be achieved in a single reactor.

- Operating flexibility and control.

-

Achieved by varying the number of cycles and levels.

- Minimal footprint.

- Potential capital cost savings by space saving and eliminating clarifiers and other equipment.

Moving Bed Bio-Reactor (MBBR)

- Compact and Modular

- Being used where space is a real constraint

- Attached growth process utilizes special plastic media for retaining more biomass in the attached form.

- However media needs to be changed / Topped up on an average of 4 – 6 years depending upon the operational characteristics.

- The units shall be either in MS or in RCC based on customer need.

FBBR

- No recycle of sludge and

- monitoring of MLSS except during start up

- Retention time : 6 – 8 hours

- Reduced power consumption

- Low sludge production

- High organics loading is possible

- Compact Tube / Inclined plate settlers used in place of huge clarifiers.

Membrane Bio-Reactor (MBR)

- Superior Treated water quality

- Improves down stream RO performance ( longer life for RO membranes, higher flux, fewer cleaning)

- Best suited for plant capacity augmentation where space is a constraint.

- Unlike ASP it does not require clarifier, and filtration system

- Increase volumetric loading

- Easy sludge handling (Less sludge wasting due to higher Sludge age)

- Removal of micro nutrients possible.